Hydraulic Turbines

DELTA DELFINI manufactures a complete line of hydraulic turbines for generating electricity with a capability from 5 kW to 10 MW, applicable to drops from 2 to 500 meters.

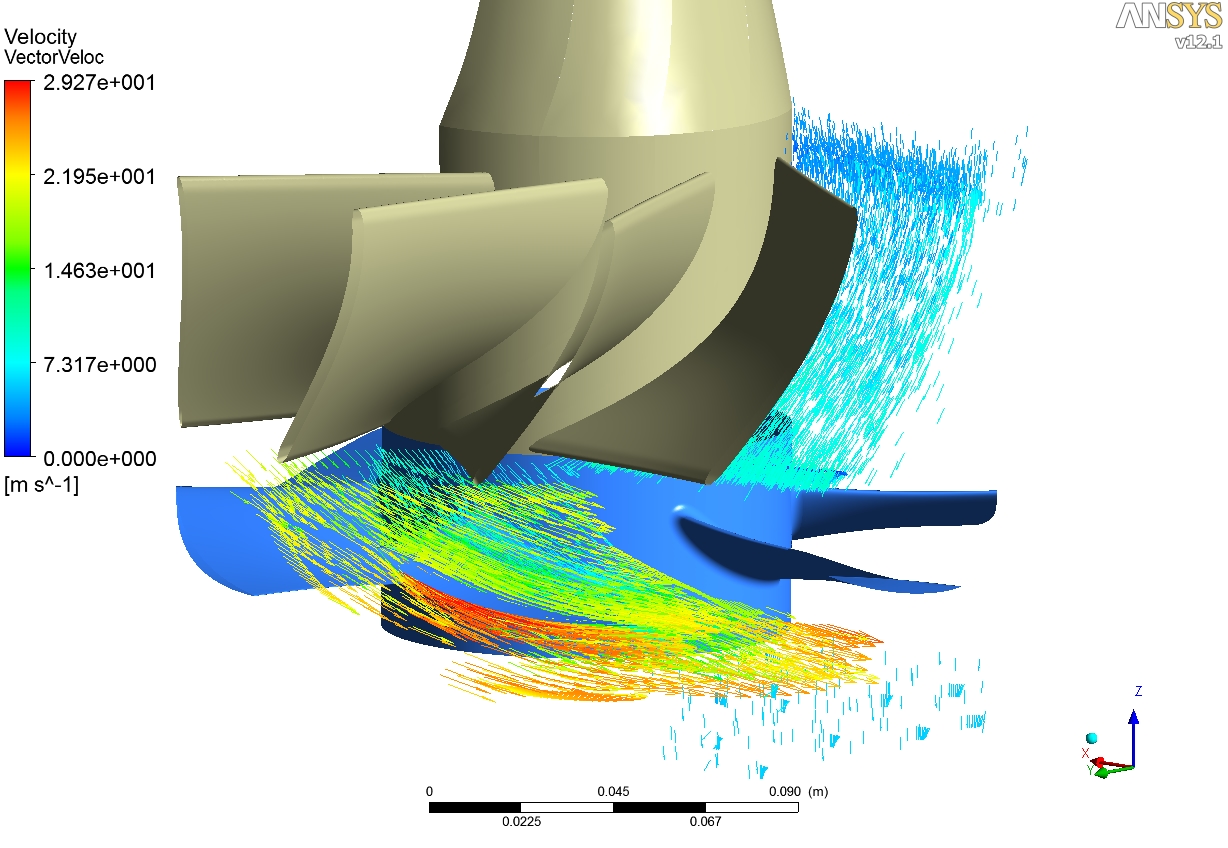

Our hydraulic turbines share our vast experience in designing and constructing high-efficiency, quality, and reliable turbomachinery. Their designs are optimized using computerized flow simulation tools (CFD), and manufacturing is performed using the best CNC equipment.

Downloads:

Pelton Turbine

Francis Turbine

Axial Turbine

Pelton Turbine

Applications Head: 50 – 500 m

Power: 5 kW – 15 MW

Characteristics:

- Ideal for low and medium flows with large drops.

- Can be supplied with a horizontal shaft of 1 or 2 jets, or with a vertical shaft of up to 6 jets.

- The runners of these turbines are made with forged stainless steel X3CrNiMo13-4 No.1.4313, totally crafted by state-of-the-art CNC equipment.

- The runners of low-power turbines can also be manufactured in a modular form, with independent blades, completely made by CNC equipment. These blades can be made of bronze, aluminum bronze, or CA-6NM stainless steels, according and depending on its application.

Francis Turbine

Applications

Head: 20 – 200 m

Power: 10 kW – 10 MW

Characteristics:

- Suitable for applications of medium head and medium flow.

- Can be manufactured with horizontal or vertical shaft.

- Economical units with fixed guide vanes can be supplied for low-power applications.

- Units with adjustable guide vanes are provided for higher power applications.

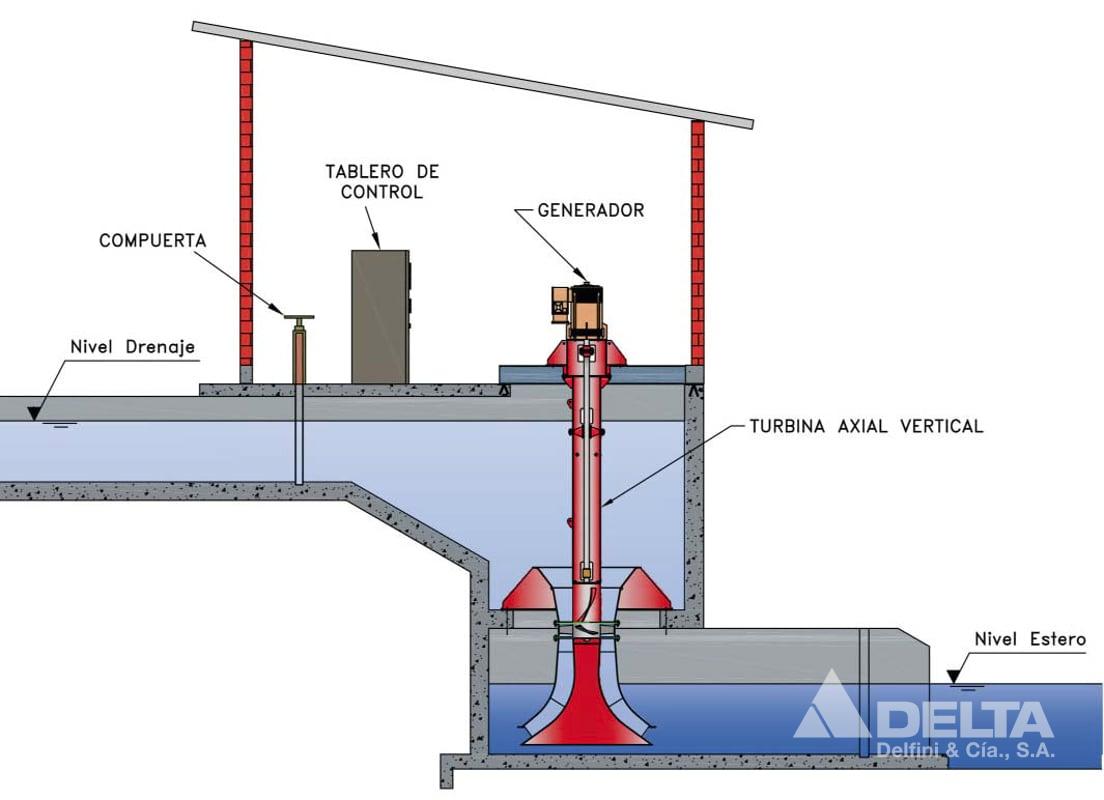

Axial Turbine

Applications Range: 2 – 20 m

Capacity: 5 kW – 3000 kW

Characteristics:

- Designed to provide an economical and reliable solution for low head applications (2 to 20 m).

- Equipped with an axial impeller with fixed blades optimized for each head and flow rate.

- Turbines are supplied with fixed guide vanes for low-capacity applications where flow control is not required.

- Turbines are provided with adjustable guide vanes in a spiral chamber or axial guide vane for applications requiring flow control.

- Manufacturing capacity ranges from 200mm to 2000mm in diameter for flow rates from 0.10 to 16 m³/s.