Axial and Mixed Flow Pumps

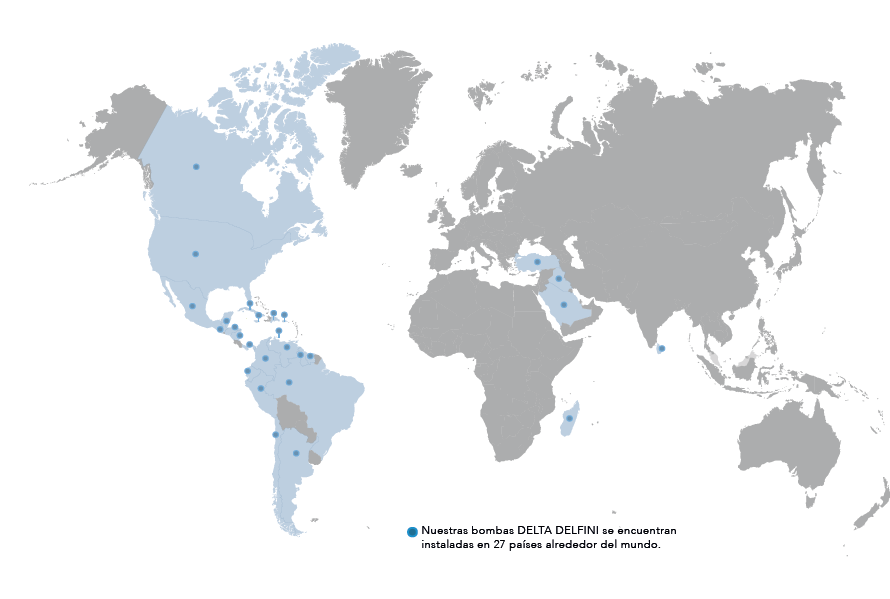

Every DELTA DELFINI axial and mixed flow pump is the result of our commitment to customer satisfaction, manufacturing excellence, and the goal of maximum performance. Each DELTA DELFINI pump is custom-made in order to meet the specific requirements of each project, thus ensuring many years of top performance. Currently, DELTA DELFINI pumps are successfully used in 27 countries under the most demanding operating conditions.

Discharge Diameters: 200 a 2,440 mm (8 a 96”).

Flow rates: 0.1 a 18 m3/s (1,500 a 285,000 USGPM).

Total Dynamic Height: Up to 25 m (82 ft) per stage.

Download:

High Efficiency

DELTA DELFINI pumps achieve efficiency peaks ranging from 80% to 91.5%, depending on the model and size. This outstanding efficiency is the result of over 45 years of continuous research and development. Our dedicated research and development team constantly refines the hydraulic and mechanical design of our pumps using the best computer simulation tools such as Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA).

Custom-made Design to Fulfill Requirements

Our industrial plant and design processes are set up to provide maximum flexibility. DELTA DELFINI will design and manufacture any pump that best fits the specific requirements of each project.

Optimized Design

The hydraulic and mechanical design is performed using Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) programs, allowing us to optimize the design of your pumps.

Construction Materials alternative

DELTA DELFINI pumps are crafted from a chosen variety of materials in order to suit specific operational conditions. Our materials range includes carbon steel, austenitic stainless steels, duplex and super duplex stainless steels, phosphor bronze, aluminum bronze, titanium, and more.

Shaft Lubrication System Alternatives

- Water-lubricated open shaft.

- Oil-lubricated jacketed shaft.

- Grease-lubricated jacketed shaft.

- External water injection-lubricated jacketed shaft.

Quick maintenance and service

Our pumps are fully modular, and after each component is machined and wielded, it allows the pump to:

- A complete disassembly as each component is manufactured with male and female fitting guides.

- An individual repair of each component before reassembling the equipment.

- Guarantee a perfect shaft alignment, a vibration-free performance with minimal usage.

- Guarantee a component interchangeability and spare parts standardization.

Seawater Pumps

Originally developed for the aquaculture industry, DELTA pumps feature specialized design elements to prevent or minimize galvanic corrosion, effectively isolating stainless steel components from carbon steel or cast iron components.

DELTA DELFINI complements its computerized pump design process with modern testing laboratories. One laboratory is dedicated to testing models up to 16 inches (400 mm) in diameter and flow rates of up to 0.4 m3/s, while another is for testing prototypes up to 48 inches (1120 mm) in diameter and flow rates of up to 3.5 m3/s.

Our laboratories allow us to accurately understand and predict the performance of each model under various operating conditions. These testing laboratories meet all requirements of the Hydraulic Institute (HI) according to ANSI/HI 14.6 2022

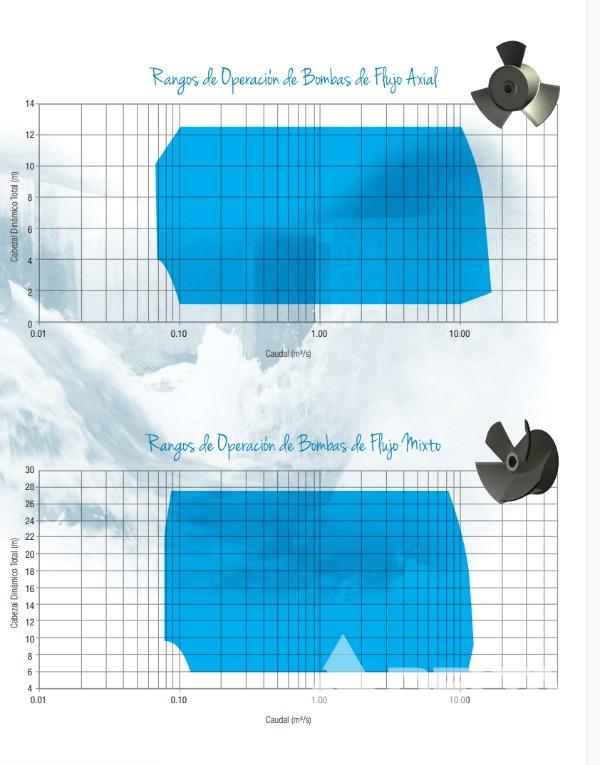

The graphics shows the operating ranges for DELTA axial and mixed flow pumps with diameters ranging from 500 to 1250 mm. The three-digit numbers on the charts represent the pump model’s diameter (050 means a 500mm discharge diameter pump).

For pump sizes not included in the charts, or to obtain complete performance curves detailing flow rate, head, rpm, efficiency, and NPSHR, please contact us at sales@deltadelfini.com

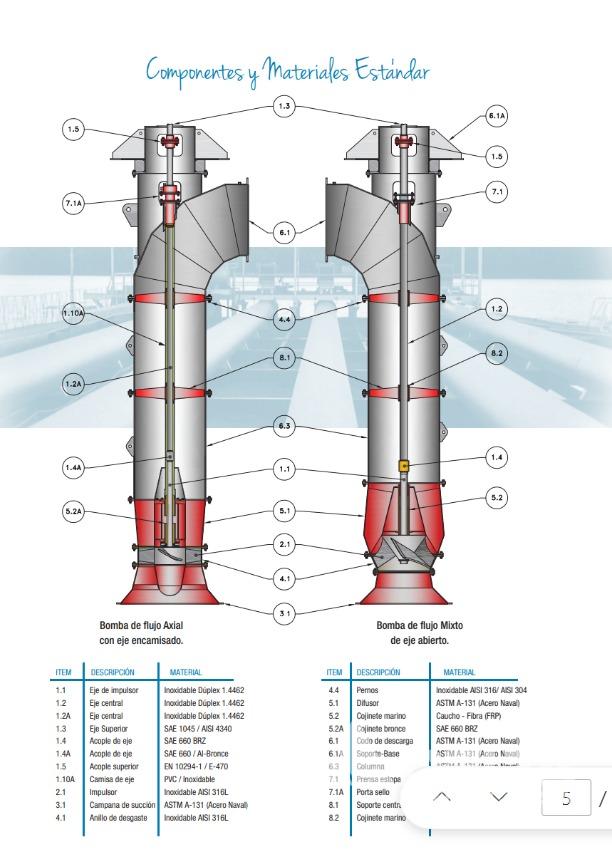

Suction Bell

The suction bell can be made of carbon steel (naval) or stainless steel. It is fully made to ensure perfect shaft alignment and also designed for a gradual reduction in the flow area. This design prevents sudden changes in the water trajectory and minimizes losses at the pump inlet.

Wear Ring

Made of Duplex stainless steel, AISI 316L, or 304L depending on its usage. It is fully crafted to provide a small clearance with the impeller, achieving high volumetric efficiency. An electrical insulation system prevents galvanic corrosion between the stainless-steel wear ring and the rest of carbon steel found in the pump. For certain usage, the wear ring can be made of carbon steel with a stainless-steel liner.

Diffuser

The diffuser can be made of carbon steel (naval) or stainless steel. The diffuser vanes are stamped with diffusion angles that allow efficient conversion of kinetic energy into pressure energy. The diffuser is totally made to ensure a proper alignment with both the pump column and the wear ring.

Shafts

For a better maintenance, the pump shaft is divided into three sections: upper shaft, central shaft, and impeller shaft. The shafts have an h8 surface finish and their standard material is Duplex stainless steel. They may vary according to the usage.

Impeller

The impeller is built with Duplex stainless steel, AISI 316L, or 304L, depending on its application and requirement. It is also manufactured by welding. Its hydraulic design using computerized flow models (CFD) and the surface finish provided by the rolled steel construction provides a higher efficiency than traditional casting methods. The impeller is structurally designed using finite element methods (FEM) not only to withstand higher loads than those faced during normal operations, but also the impact loads due to accidental inclusion of solid objects. All impellers are dynamically balanced.

Column

The pump column is a flanged construction made of carbon steel (naval) plate welded by automatic submerged arc processes. The standard plate thickness is 8 mm for models 050 to 063, 10 mm for models 071 to 125, and 12 mm or above for larger models. Pump column sections are made between centers to ensure perfect alignment with other components.

Central Supports

Central supports are made of carbon steel (naval) and fully crafted to ensure perfect shaft alignment. Their modular design simplifies the removal of worn out bearings and the installation of new ones.

Bolts

All bolts are made of stainless steel AISI 316 or 304. Additionally, these are electrically insulated to prevent galvanic corrosion.

Discharge Elbow

These are made of carbon steel (naval), flanged construction, and totally crafted to ensure a perfect alignment. The plate thicknesses used in its construction are the same used in the pump column. Moreover, they can be supplied for discharge above or below the pump support level.

Upper Shaft Coupling

The power transmission between the upper shaft and the central shaft is accomplished through a flanged coupling, carefully designed to withstand mechanical stress and allow a quick disassembly, thus facilitating the equipment maintenance.

Lower Shaft Coupling

Its standard construction is made of phosphorous bronze or aluminum bronze. They are threaded but they can be made of special non-threaded steels with keyways and split rings which are easy to remove.

Surface Finish

The standard finish of DELTA DELFINI pumps displays two layers of epoxy paint. Coatings are applied on a metal surface blasted to “near-white” according to SSPC-SP10 specifications. The minimum thickness of this coating is 0.25 – 0.30 mm.

Ball Bearing

DELTA DELFINI pumps are supplied with a hollow shaft bearing for applications with power transmission by V-belts and for the transmission equipment that does not support thrust load. This uniquely designed ball bearing supports axial thrust of the shaft and allows vertical adjustment of the impeller. Bearings are perfectly sized to ensure a minimum operating life of 30,000 hours. These bearing incorporate an integral oil pump that allows lubrication to the bearings. Solid shaft ball bearings are also available.

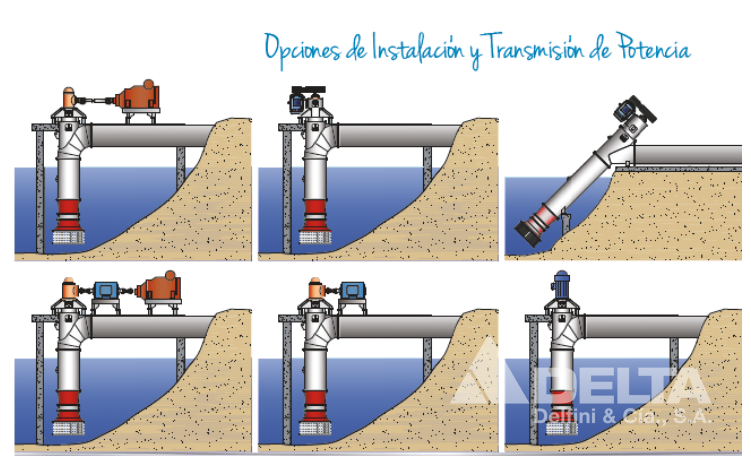

DELTA DELFINI offers a variety of power transmission systems made to your specific needs. The installation configurations provided by DELTA DELFINI, as illustrated in the pictures, include the following:

- Vertical pump with speed reducer – cardan shaft – Diesel engine.

- Vertical pump with speed reducer – cardan shaft – horizontal electric motor.

- Vertical pump with speed reducer – cardan shaft – horizontal dual-shaft electric motor – cardan shaft – Diesel engine. Dual System.

- Vertical pump with vertical electric motor directly coupled to the pump shaft.

- Vertical pump with belt and pulley transmission – electric motor mounted on an integral pump base.

- Inclined pump with belt and pulley transmission – electric motor mounted on an integral pump base.

- Horizontal pump with direct transmission -or belt and pulley transmission- with electric motor.

As a complement to our pump line, DELTA DELFINI manufactures all the following accessories for the design and operation of pumping stations:

- Suction strainers.

- Concentric and eccentric diffuser cones.

- Discharge elbows and discharge pipes.

- Tilting gates.

- Structural components for the pumping station.

- Gantries for maintenance